Happy New Year 2016 - Platinum

January 15th 2016

Happy New Year everyone!

Late last year I made a Tsavorite Garnet engagement ring. Whilst the Garnet was the most amazing green colour I have seen in a gemstone in a long while, it is the precious metal Platinum that was used for the ring that I am going to write about in this article.

When I ask the owner of a Platinum piece of jewellery "which Platinum alloy was it made in?" I usually get the reply of "I thought Platinum was Platinum?" Nothing could be further from the truth when it comes to Platinum alloys.

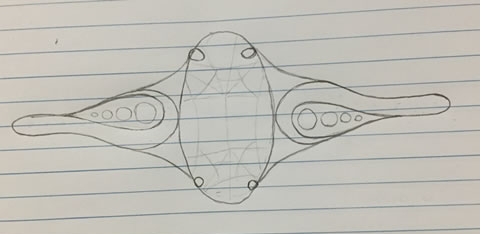

Before we get into this article on Platinum I would like to write a little about this ring. To make it his own unique design my customer provided this sketch for the ring to be based upon.

Tsavorite Garnets are quite rare so rather than limit ourselves to oval gems as in the sketch above it was decided to select the gem first and then modify the design around it if needed.

In the end a 1 carat round cut gemstone was selected. Using the customers sketch as a guide I digitally created the design below modifying it to suit a round gem.

With the design approved we set about making a silver draft to confirm both the design and finger size. With that done we were now ready to make the ring in Platinum. The finished ring is shown below and a very happy customer informed me just recently that the proposal was accepted and his fiancee loves the ring!

For this ring I used a Platinum 950/Cobalt alloy with cold working of the band and burnishing of the surface to increase the Platinum alloys hardness as this was to be an every day ring that would eventually have a wedding ring rubbing next to it.

Time to explain a bit about Platinum so that last bit makes more sense :)

The Purity of Platinum alloys

Platinum alloys used for jewellery are formed by adding other metals to pure Platinum. Some Platinum alloys contain 95% pure Platinum and are referred to as Platinum 950. Today there are quite a few alloys that contain 90% pure Platinum and are referred to as Platinum 900.

This variation in pure Platinum content is used to both alter properties of the alloy to suit an application and also to affect cost.

For example a harder alloy may be required for a piece of jewellery that is worn on the hand every day but a softer alloy used for a piece of jewellery that requires a lot of intricate detail or setting work and gets less rough wear, such as a pendant or earrings.

What goes into a Platinum alloy?

The two most common metals added to Platinum are Iridium and Cobalt. That said copper, gold, ruthenium, indium and gallium are also used in alloys.

So how many Platinum alloys are there? The answer is lots but here is a list of some of the more common ones:

- Platinum 900/Iridium

- Platinum 950/Iridium

- Platinum 950/Cobalt

- Platinum 900/Cobalt/Copper

- Platinum 950/Palladium

- Platinum 900/Palladium

- Platinum 900/Gold

- Platinum 950/Ruthenium

- Platinum 950/Indium/Gallium

Platinum is softer than gold isn`t it?

The answer to this question very much depends on the Platinum alloy and also the way in which it has been treated during the manufacturing process of the piece of jewellery.

On the Vickers hardness scale the Platinum alloys I listed above vary in hardness from 60 to 160. The lower the number the softer the alloy. For a point of reference yellow gold alloys are in the 120-125 range on the Vickers scale.

With the right working of some Platinum alloys during manufacturing, hardness can be increased to as high as 270. I referred to this when I mentioned the cold working of the Tsavorite Garnet ring band and the burnishing of the surface. A full description of that process is an article for another day however.

You can imagine that a mens wedding ring made from a Platinum alloy with a hardness of just 60 would be scratched and marked in very little time with anything other than the most occasional wear.

Why does any of this matter?

The most basic thing to know is are you buying Platinum with a purity of 90 or 95 percent? Many Platinum items are hallmarked simply as "Pt" or "Platinum".

If it is not on the invoice and you do not ask at the time of purchase then you may never know. If the seller of the Platinum item cannot tell you then you really should be thinking about whether you want to buy from someone who does not know what they are selling.

If you need to have work done on your Platinum jewellery at a later date then you need to match your Platinum alloy. Platinum alloys may vary in colour to some degree so adding two different Platinum alloys together may give you a colour variation.

This is very much the case if at some stage you intend to put another ring, such as a wedding ring, next to your Platinum engagement ring. As with all the custom engagement ring designs I create we plan ahead for the intended wedding ring.

In the case of this Tsavorite Garnet ring a straight wedding ring was desired. Knowing the Platinum alloy that the engagement ring was made in and with some slight alterations to the engagement ring design to allow them to sit neatly together, the creation of the wedding ring down the road will be a straight forward process.

A jeweller cannot just look at a piece of Platinum jewellery and tell you what Platinum alloy you have. If it is not fully hallmarked then you will need to take a sample of the alloy and send it to a metallurgist to determine this. A costly exercise that will more than likely damage your piece of jewellery in some way.

Some advice for buying Platinum jewellery.

- Make sure the invoice clearly states what type of Platinum alloy is used. The details you need are the Platinum purity and what alloys are added to make up the rest of the alloy.

Make sure that you understand the characteristics of the Platinum alloy you are buying. If the seller cannot explain it to you then that should tell you something.

- Be aware that most Platinum alloys do not solder or weld very well so repairing them may not be an option or the result may be less than desirable. Take care of your Platinum jewellery. It is special.

- Go back to the same jeweller that made the Platinum piece of jewellery for it to be serviced. I recommend this with all jewellery.

Most of the jewellery in the world today is not hand made but rather mass produced from cast wax injected models. The point here is that some Platinum alloys are great for mass producing jewellery but they might not be the right alloy for your piece of jewellery and how you want to wear it.